Proposal for a new surface processing technique –Successful formation of a silicon needle–

Research Press Release | March 24, 2016

Successful formation of a silicon needle by the radiation force of an optical vortex and visualization of its formation process for the first time in the world!

|

Key Points |

The research group including Professor Takashige Omatsu of Chiba University and Professor Ryuji Morita of Hokkaido University, for the first time in the world, has succeeded in discovering the novel physical phenomenon of monocrystalline silicon needle formation by irradiating a silicon monocrystal with laser light (an optical vortex1) that has a helical wavefront and a doughnut-shaped (having a hole) intensity profile as well as in visualizing the formation process. This research is conducted as a part of JST Strategic Basic Research Programs. |

|

|

Background |

The problem of silicon surface processing with lasers Silicon monocrystals are known as one of the most widely used electronic materials today. The potential capabilities of silicon are greatly improved by nano-processing. However, in conventional silicon surface processing with lasers, the surface often becomes polycrystalline or amorphous2, and it has been extremely difficult to create nano-structures on the surface while keeping it monocrystalline. |

|

|

Result |

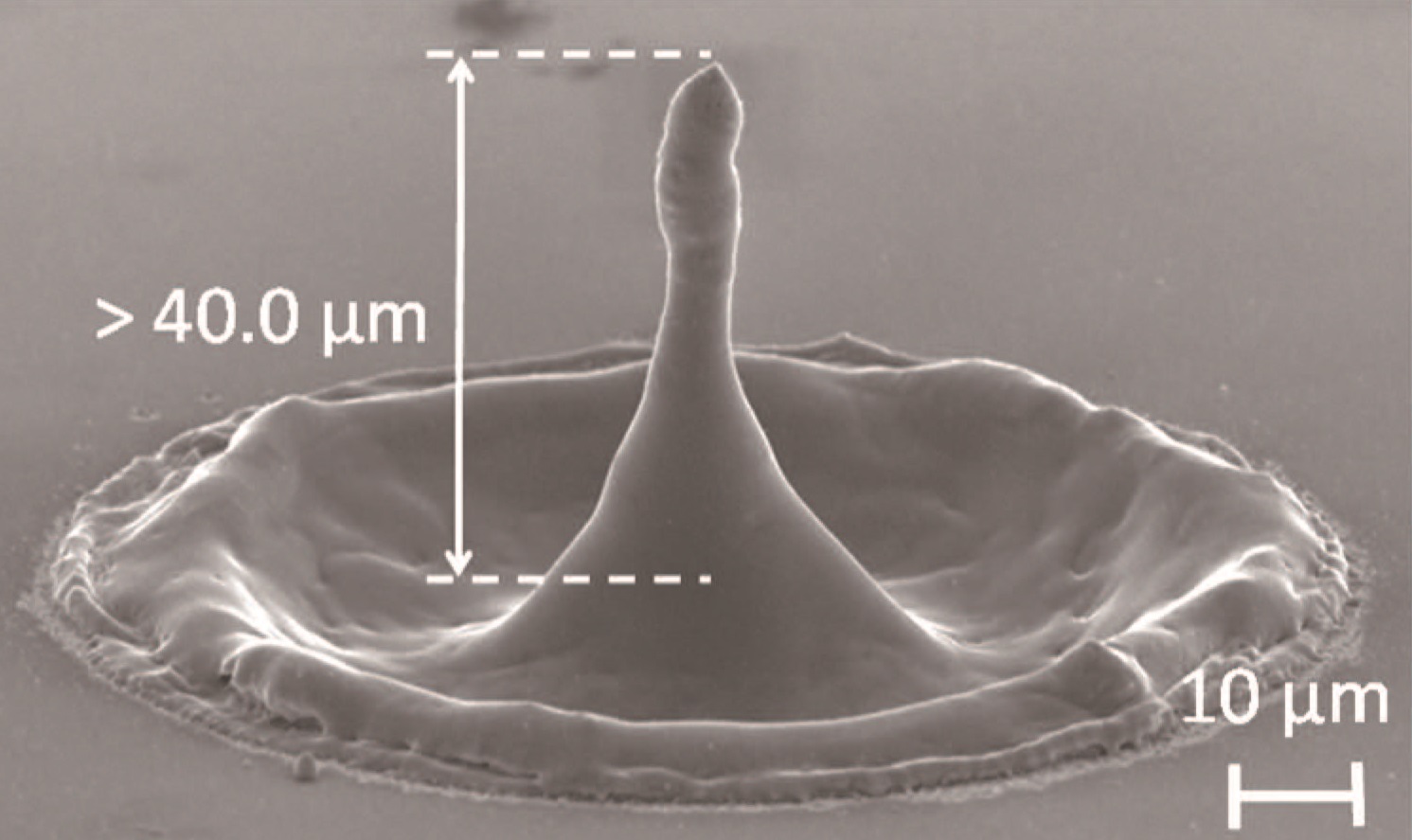

First discovery of silicon needles in the world We discovered a new phenomenon for the first time in the world: when irradiating a silicon monocrystal substrate with laser light (an optical vortex) that has a helical wavefront and a doughnut-shaped (having a hole) intensity profile, a monocrystalline silicon needle is formed on the substrate through the unique effect of the radiation force3 of the optical vortex. We also discovered that the height of the needle exceeds 40 micrometers (1 micrometer is 10-6 meters). |

|

|

Anticipated Outcomes |

This result, that it is possible to control the micro-structure of silicon without changing its crystal properties by using the radiation force of an optical vortex, will have a great impact on optics, such as for optical manipulation4. This result also proposes a new surface processing technique using the radiation force of light and it can be expected to have various ripple effects in the future, such as to silicon photonics. For example, just by using light irradiation, it will be possible to create functional devices to support advanced technologies, including silicon surface processing techniques to replace moth-eye structures5, and silicon monocrystal painless needles with low allergenicity for the human body. The use of the radiation force of optical vortices can also make silicon droplets fly in a straight line so as to pass through “the eye of a needle,” and this technique can also be applied to various functional materials such as magnetic substances. It will also have an extremely large impact as a new technique for creating structures for making fine droplets fly to arbitrary positions in three dimensions, known as printable electronics. |

|

| Terms |

1 Optical vortex: The wavefront of light means an equiphase surface. If this surface has a helical shape (a helical wavefront), the light is called an optical vortex. The helical wavefront of an optical vortex is defined with the winding number ℓ (an integer) of the helix of the wave surface for the wavelength of the light. 2 Amorphous (non-crystalline): A substance whose atoms are not arranged periodically, as opposed to a crystal in which the atoms are arranged periodically. Glass is a typical example. 3 Radiation force: The power to act upon a substance along the flow of light energy is called radiation force. The radiation force of an optical vortex with a helical wavefront, in addition to having radiation force in the forward direction in which the light is propagating, also has radiation force in the circumferential direction along the doughnut-shaped intensity profile. The radiation force in the circumferential direction can be controlled by ℓ, which represents the winding number of the helix of the optical vortex. 4 Optical manipulation: Capturing or manipulating micro-particles in a non-destructive and non-contact way by using the radiation pressure of laser light. Applied in the field of medical biology. 5 Moth-eye structure: A structure that has a smaller period than the wavelength of a light, processed this way so as to continuously change the refractive index for the light, in order to suppress the reflection of the light. The surface of a solar cell may be processed this way. This structure can also suppress water resistance and air resistance, so it is also applied to the outer walls such as of airplanes and automobiles. |

|

| Inquiries | Professor Ryuji MORITA Laboratry of Nonlinear Optics and Laser Physics, Division of Applied Physics, Graduate School of Engineering, Hokkaido University morita[at]eng.hokudai.ac.jp |

|

|

Japanese Link |

世界初、光渦の輻射が創るシリコンニードルとその形成過程の可視化に成功 〜新しい表面加工技術の提案〜 (02.25.2016) | |

|

Publications |

Picosecond optical vortex pulse illumination forms a monocrystalline silicon needle, Scientific Reports (02.24.2016) |

|