Novel material from Hokkaido: Successful mass production of fermented nanocellulose

Research Press Release | September 25, 2013

-

Photo 1 Nano-fibrillated bacterial cellulose (NFBC)

Photo 1 Nano-fibrillated bacterial cellulose (NFBC) -

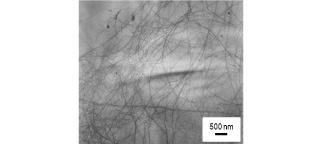

Photo 2 Electron microscopic photograph of NFBC

Photo 2 Electron microscopic photograph of NFBC

| Press Release | ||

|---|---|---|

| Key Points |

・Hokkaido University has successfully synthesized fermented nanocellulose, a novel material consisting of ultrafine cellulose nanofibers with only 20 nm in diameter, by utilizing Gluconacetobacter intermedius (NEDO-01) to improve the culture process. ・Further, Hokkaido University and Nippon Beet Sugar Manufacturing Co., Ltd. have used a large-scale fermentor for the successful mass production of fermented nanocellulose from low-cost raw materials such as waste glycerol and molasses. ・It holds the potential for use in a wide range of fields, including foods, cosmetics, specialty papers, electronics, and medical applications. |

|

| Overview | Associate Professor Kenji Tajima of the Faculty of Engineering, Hokkaido University and his research group have discovered a highly efficient method of synthesizing cellulose (bacterial cellulose (BC)) from raw materials such as waste glycerol and sugars by using a bacterial strain (scientific name: Gluconacetobacter intermedius (NEDO-01)) newly isolated from fruit. By further improving the culture method, they have also succeeded in preparing the material to form an extremely homogenous aqueous dispersion (patent pending: patent application no. 2012-289043).

This is fermented nanacellulose (nanofibrillated) bacterial cellulose) (NFBC)) (Figure 1). The fermented nanocellulose fibers formed by NEDO-01 are not only ultra-fine, with an average diameter of 20 nm, but are also extremely dispersible and fluid (Figures 1 and 2), and can be used in a wide range of fields, including foods, cosmetics, specialty papers, electronics, and medical care. Hokkaido University and Nippon Beet Sugar Manufacturing. Co., Ltd. (hereinafter “Nippon Beet Sugar Manufacturing”) launched a joint research project in April this year on the mass production of fermented cellulose, building on this fermented nanocellulose production technology and intellectual property. Nippon Beet Sugar Manufacturing, which manufactures sugar from beet in Hokkaido, has succeeded utilizing its expertise in sugar manufacture and microorganism culture techniques to achieve the mass production of fermented nanocellulose from raw materials such as molasses, by using a large-scale fermentor. |

|

| Inquiries |

Kenji Tajima, Associate Professor, Graduate School of Engineering, Hokkaido University TEL & FAX: +81-11-706-6607 e-mail: ktajima@eng.hokudai.ac.jp Hirokatsu Uchino, Vice-President for Research, Nippon Beet Sugar Manufacturing Co.Ltd. TEL: +81-155-48-4102 FAX: +81-155-47-0711 e-mail: utin@nitten.co.jp Taizo Nagura, Deputy Director, Food Products Division, Nippon Beet Sugar Manufacturing Co.Ltd. TEL: +81-3-6414-5535 FAX: +81-3-6414-3984 e-mail: nagu@nitten.co.jp |

|

|

Japanese Link |

http://www.hokudai.ac.jp/news/2013/09/post-267.html | |