“Smart synthesis” of polymers — Making the whole process sustainable

Research Highlight | September 06, 2021

This series of interviews introduces the five Principal Investigators (PIs) of 創成特定研究事業 (sōsei tokutei kenkyū jigyō), the university-wide interdisciplinary research promotion program to foster early- and mid-career researchers.

From plastic trays at supermarkets to various devices inside computers, our daily lives are filled with things that are made from organic and polymeric materials. “Those products are all fantastic, but the problem lies in their synthetic processes,” points out Professor Toshifumi Satoh of Hokkaido University’s Graduate School of Engineering, who has taken up the challenge to create “Smart synthetic method.”

Satoh and his colleagues proposed the idea of “Smart synthesis,” which aims to minimize the use of harmful chemicals and solvents for cleaner and more sustainable polymeric synthesis.

Q. Please tell us about the background and purpose of the research project.

Toshifumi Satoh: Both universities and companies have been developing high-performance organic polymers that are “clean and sustainable.” However, a large amount of harmful chemicals and organic solvents are still used in their synthetic processes. Processing such harmful substances requires a lot of energy, putting a significant burden on the environment. That’s the reality of polymeric synthesis at the moment.

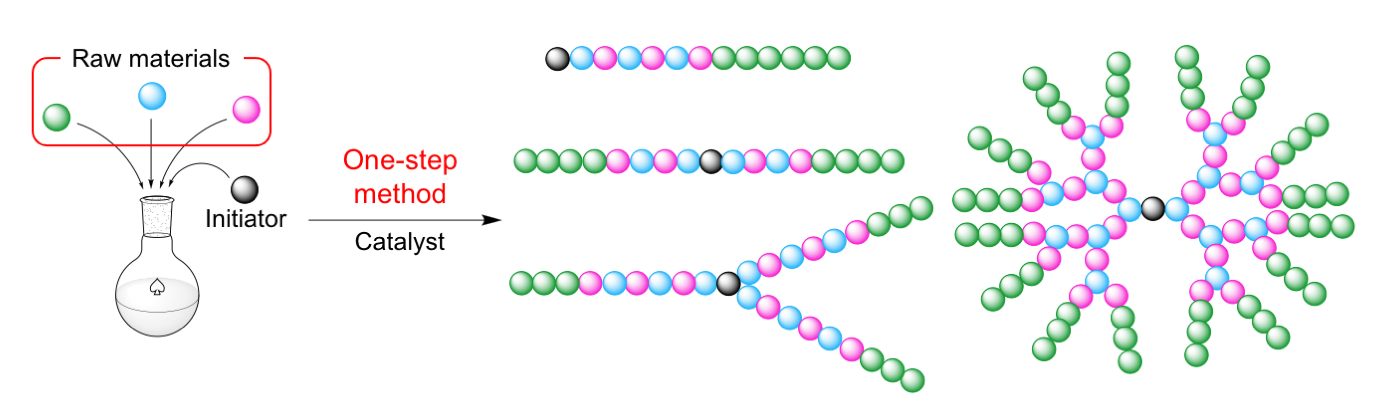

We aim to change that situation. More specifically, we are working to develop novel synthetic methods that use metal-free, less toxic organocatalysts, instead of toxic organometallic catalysts, to produce biodegradable or biocompatible polymers. Also, we are developing what is called the “One-step method” to produce polymeric materials that were previously synthesized by multi-step reactions. In our method, it only takes one step, thus significantly reduces the amount of reagents and solvents used. The resulting polymer was proved functionary equivalent to the one made with conventional methods.

In the “One-step method,” we only need to put all starting materials and other reagents in a single flask. The reactions then occur in a sequential manner to produce the intended polymer. It’s as simple as that. Some scientists have introduced the method in organic chemistry, but there aren’t many examples of applying it to plastic synthesis, as we have done. The One-step method forms the basis of the Smart synthetic method we propose.

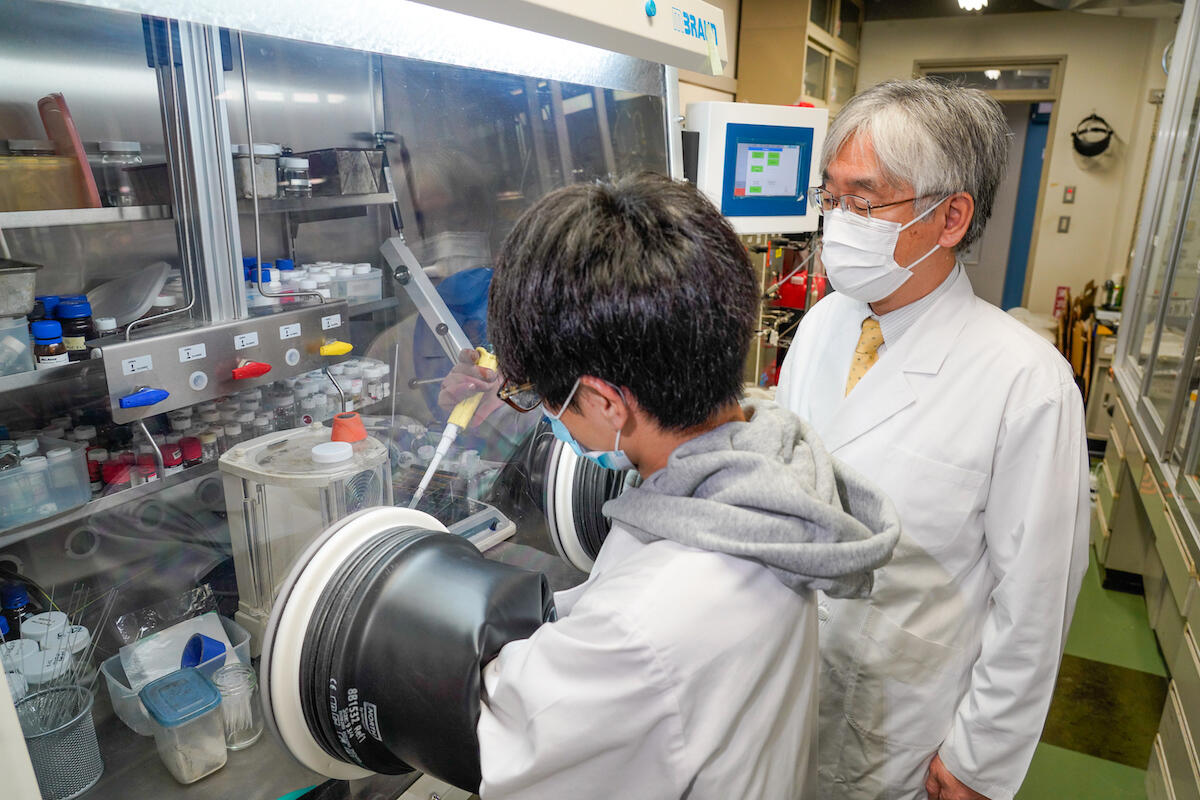

It is a challenging task to regulate multiple reactions in a single flask. “Simple regulations are already in our hands, and the precision is gradually improving,” says Satoh.

Our laboratory is working to apply the One-step method to the production of flexible electronic devices, nanoparticles for gene delivery, and polymeric materials that are responsive to various stimuli. Researchers around the world are working hard to develop such materials, and we are taking on this challenge together with collaborators in Taiwan, China, and France.

Q. What are your thoughts on training students and young researchers who are participating in your project?

Satoh: In my lectures, I often tell my students, “It is my mission as faculty to pull out 120 percent of your potential.” To put that into practice, I first need to carry out world-class research, demonstrate cutting-edge experiments, and educate students so that they can proudly present their results in papers and at international meetings.

However, in reality, there isn’t so much I can do on my own. This is where my collaborators from overseas, who share the same ambitions for both research and education, can always support me. For instance, the double-degree program signed between National Taiwan University and Hokkaido University can be used to send out students abroad. I believe students grow dramatically when they pursue a goal in an unfamiliar environment with a different language and culture. I hope the program gives such opportunities.

Q: Are there many companies that are interested in the Smart synthesis method?

Satoh: Yes. As some companies have already taken initiatives in developing this method, I believe it is a shared mission of the whole chemical industry, regardless of their position, to develop clean and sustainable synthetic methods.

As you know, there are ongoing global-scale efforts to reduce the use of petroleum-based plastic. However, the amount of such plastic used in the world is enormous. To produce the same amount of biodegradable or biocompatible plastic as the replacement requires the use of a vast amount of harmful chemicals and solvents.

To solve this dilemma, I want to share the vision of Smart synthesis, and what it will enable in the long term, with as many researchers in the chemical industry as possible, especially with the young ones who are aspired to build a sustainable future.

Special chromatography equipment to measure the absolute molecular weight of the polymers they produce.

Q. What are the advantages of doing your research at Hokkaido University?

Satoh: I have two answers to that question. As exemplified by the cross-coupling reaction developed by Professor Akira Suzuki, who was awarded the Nobel Prize in Chemistry in 2010, Hokkaido University has a long history and proven record in synthetic chemistry, which is also known as Japan’s specialty.

In our laboratory, which deals with polymers, each student learns various synthetic methodologies than focusing just on a single method. That’s why we are able to produce researchers who have a thorough understanding of both basics and applications of polymer synthesis. As they know the basics, they can suggest various applications. In that sense, we take full advantage of our specialties.

The other strength of the university is the abundance of scientists who are researching green materials and biomass, making a superb environment to collaborate across disciplines. The university also puts a lot of effort to contribute to the Sustainable Development Goals (SDGs), and was named top in Japan in the THE Impact Rankings in 2020 and 2021. It is the perfect ground to pursue our goal of making all those functional polymers entail clean and sustainable, from development, production, collection after use, and reuse.

In order to incorporate our efforts into real-world policies, we need to work with humanities researchers too. I envision the future in which Hokkaido University, with its rich greenery, will advocate new standards for manufacturing by mobilizing the power of each department.

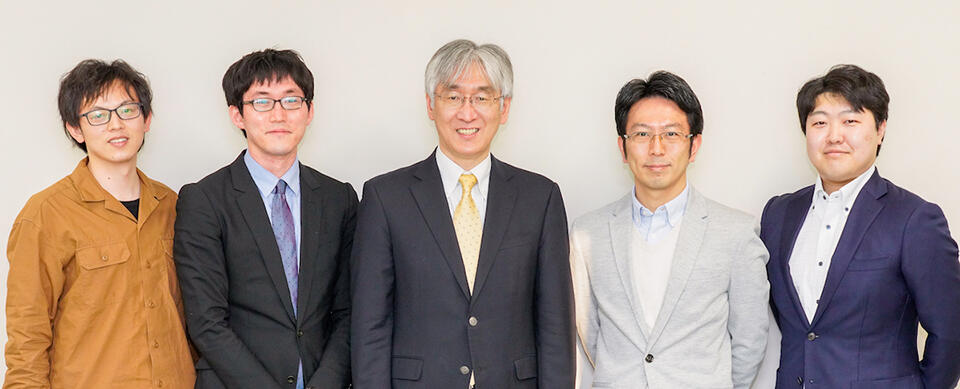

From the left: Xiaochao Xia, Faculty of Engineering; Yusuke Sato, Faculty of Pharmaceutical Sciences; Toshifumi Satoh, Faculty of Engineering; Hideyuki Mitomo, Research Institute for Electronic Science; and Takuya Isono, Faculty of Engineering

The original interview in Japanese is available here.

Translated and rearranged by Naoki Namba

Laboratory Webpage:

https://poly-ac.eng.hokudai.ac.jp/index_e.html

Related article:

Hideyoshi Harashima, Becoming a gene therapeutics hub through contemporary nanopharmaceuticals