UV-to-red light converting films accelerate plant growth

Research Press Release | October 26, 2022

Plastic sheets coated with an Eu3+ film that converts UV light to red light were able to accelerate growth of vegetal plants and trees.

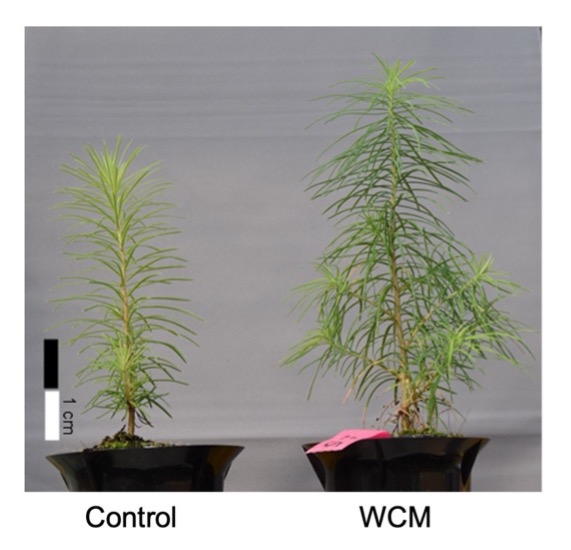

Japanese larch tree seedlings grown without (left) and with (right) the use of a wavelength converting material (WCM) sheet. (Sunao Shoji et al. Scientific Reports. October 26, 2022)

An interdisciplinary team from Hokkaido University’s Engineering and Agriculture departments and the Institute for Chemical Reaction Design and Discovery (WPI-ICReDD) has developed a europium-based thin-film coating that they demonstrated accelerates both vegetal plant and tree growth. This technology can improve plant production speed and has the potential to help address global food supply issues.

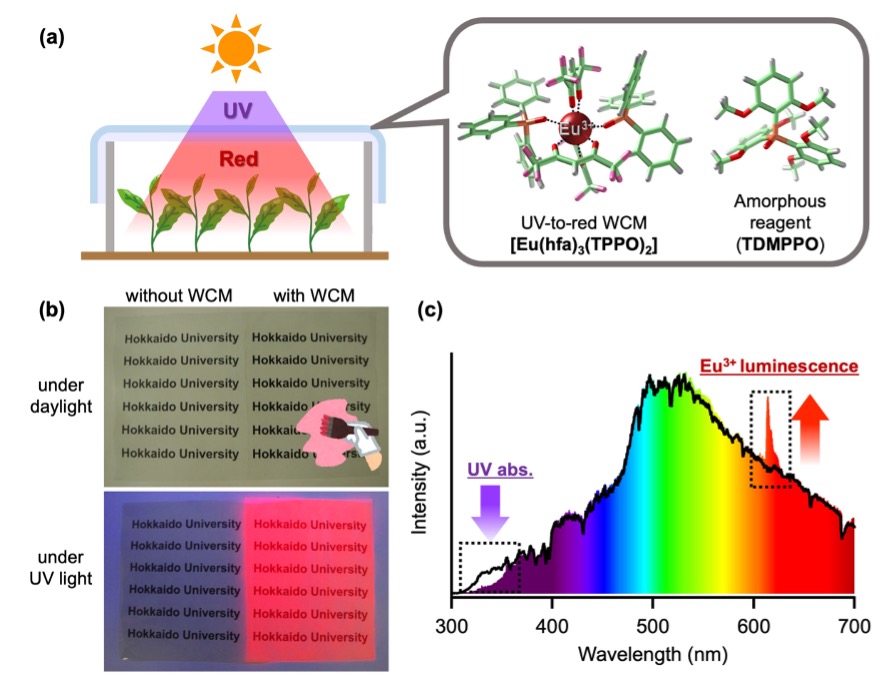

Plants convert visible light to energy via a process called photosynthesis. In addition to visible light, sunlight also contains ultraviolet (UV) light. Researchers in this study aimed to provide plants with additional visible light to use in photosynthesis by employing a wavelength converting material (WCM) that can convert the UV light into red light.

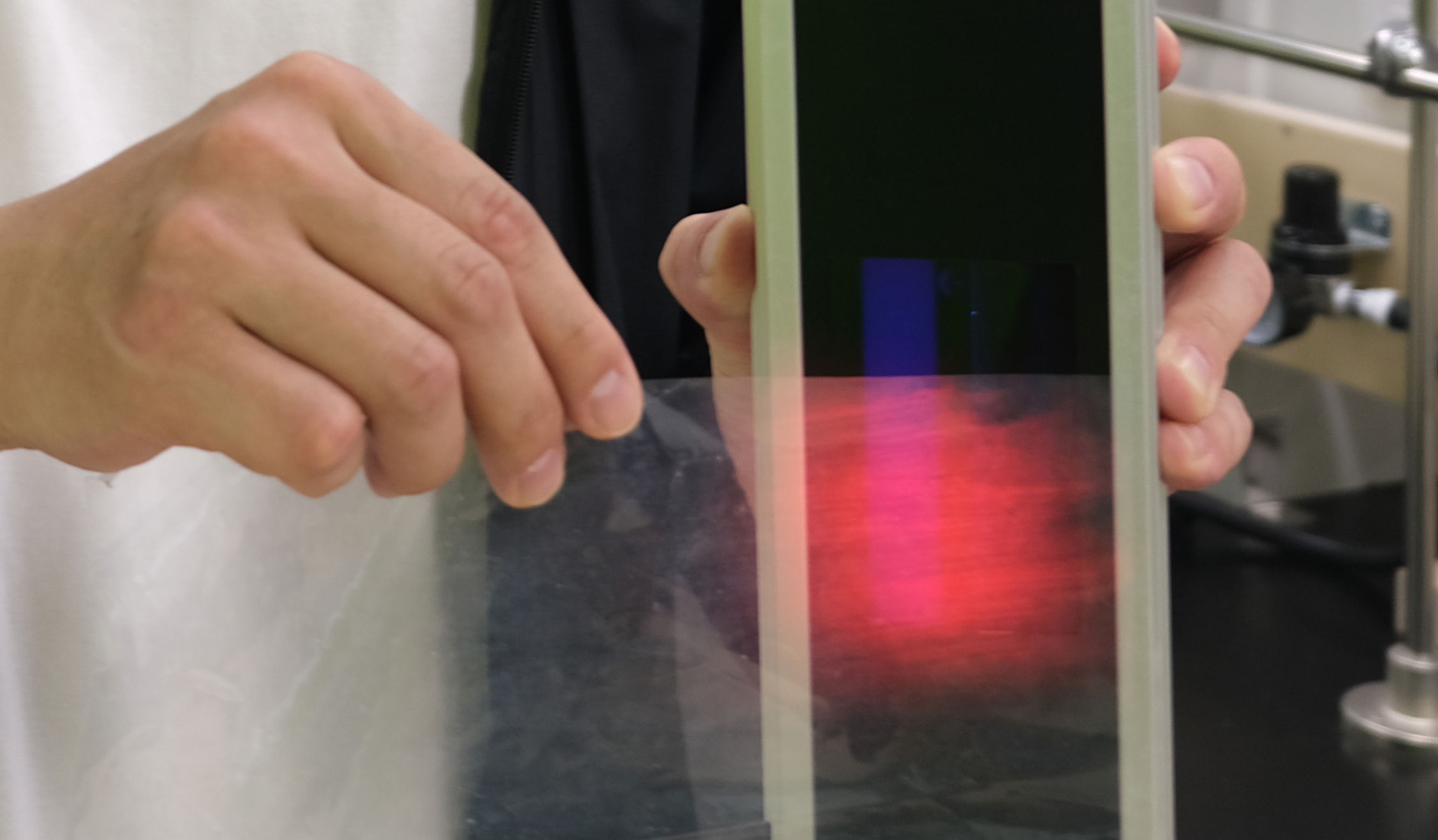

Researchers developed a WCM based on a europium complex and made a thin-film coating that can be applied to commercially available plastic sheets. Researchers not only showed that the film converts UV light to red light, but also that the film does not block any of the beneficial visible light from the sun. The film was then tested by comparing plant growth using sheets with and without the WCM coating. Trials were performed for both Swiss chard, a vegetal plant, and Japanese larch trees. In summer, when days are long and sun irradiation is strong, no significant difference was observed for Swiss chard when using the WCM films. In winter, however, when days are shorter and sunlight is weaker, Swiss chard plants grown using the WCM films showed 1.2 times greater plant height and 1.4 times greater biomass after 63 days. Researchers attributed this accelerated growth to the increased supply of red light provided by the WCM films.

(a) Schematic of WCM film converting UV light to red light (left) and molecular structure of film components (right). (b) Photos of plastic sheets with and without WCM coating. (c) Solar spectrum showing wavelengths absorbed and emitted by the WCM film. (Sunao Shoji et al. Scientific Reports. October 26, 2022)

Trials involving Japanese larch trees also showed accelerated growth. Seedlings showed a higher relative growth rate in the initial 4 months of growth, resulting in a stem diameter 1.2-fold larger and total biomass 1.4-fold larger than trees grown without the WCM coating. Critically, this enabled the seedlings to reach the standard size for planting in the forestry of Hokkaido within one year. Use of WCM films could shorten the growth period of seedlings from two years to one year, resulting in more cost-efficient plant production.

This technology also has the potential to help with food security issues in colder climates and is beneficial because it does not require any electricity to operate. Researchers see the customizability of the technology as especially promising.

“By using a coating of wavelength changing material, we were able to successfully create a transparent film and demonstrate its ability to accelerate plant growth,” said lead author Sunao Shoji. “By rationally designing the light-emitting ion, we can freely control the color of emitted light to be other colors like green or yellow, so we expect to be able to create wavelength converting films that are optimized for different plant types. This opens a large avenue of future development for next generation agricultural and forestry engineering.”

(Left to Right) Sunao Shoji, Yuichi Kitagawa, Yasuchika Hasegawa of the research team. (Photo provided by ICReDD)

Original Article:

Sunao Shoji, Hideyuki Saito, Yutaka Jitsuyama, Kotono Tomita, Qiang Haoyang, Yukiho Sakurai, Yuhei Okazaki, Kota Aikawa, Yuki Konishi, Kensei Sasaki, Koji Fushimi, Yuichi Kitagawa, Takashi Suzuki, and Yasuchika Hasegawa. Plant growth acceleration using a transparent Eu3+-painted UV-to-red conversion film. Scientific Reports. October 26, 2022.

DOI: 10.1038/s41598-022-21427-6

Funding:

This work was supported by the Hokkaido University Research and Education Center for Robust Agriculture, Forestry and Fisheries Industry. This work was partially supported by Grant-in-Aid for Cross-departmental Young Researcher Grants from Hokkaido University (to S.S.). This work was partially supported by the Japan Society for the Promotion of Science (JSPS) KAKENHI Grant Numbers JP22K14741 (to S.S.), JP20K21201 (to Y.H.), JP22H02152 (to Y.H.), JP22H04516 (to Y.H.), JP21H02180 (to T.S.), JP19K22902 (to H.S.), JP21K18969 (to Y.K.), and JP20H02748 (to Y.K.). This work was also partially supported by the Institute for Chemical Reaction Design and Discovery (ICReDD), established by the World Premier International Research Initiative (WPI) of MEXT, Japan.

Contacts:

Specially Appointed Assistant Professor Sunao Shoji

Institute for Chemical Reaction Design and Discovery (WPI-ICReDD); Faculty of Engineering

Hokkaido University

Email: s-shoji[at]icredd.hokudai.ac.jp

Professor Yasuchika Hasegawa

Institute for Chemical Reaction Design and Discovery (WPI-ICReDD); Faculty of Engineering

Hokkaido University

Email: hasegaway[at]eng.hokudai.ac.jp

Collin Stecker (Public Relations and Outreach)

Institute for Chemical Reaction Design and Discovery (WPI-ICReDD)

Hokkaido University

Tel: +81-11-706-9646

E-mail: public_relations[at]icredd.hokudai.ac.jp

Sohail Keegan Pinto (International Public Relations Specialist)

Public Relations Division

Hokkaido University

Tel: +81-11-706-2185

Email: en-press[at]general.hokudai.ac.jp

Related Press Releases:

Linked lanthanides shine light on field of crystal engineering

Chemical reaction design goes virtual

Novel computer-assisted chemical synthesis method cuts research time and cost