Methane gas in cattle breath and manure has a higher greenhouse effect than carbon dioxide, and is one of the causes of global warming. On the other hand, this methane can also be utilized as biomass energy through appropriate treatment. Associate Professor Shiho Ishikawa of the Environmental Engineering Department, Faculty of Engineering, spoke about her research to solve the various issues surrounding the cattle industry and build a recycling-oriented society.

The abundant potential of Hokkaido’s biomass

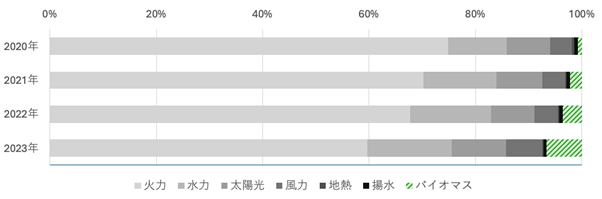

In Hokkaido, the amount of electricity generated from renewable energy sources is now growing rapidly. The graph below shows the percentage of electricity generated from renewable energy sources in the Hokkaido area, including hydropower, solar power, wind power and biomass. Of these, particular attention should be paid to biomass power generation, which is shown in green in the graph. Biomass is a term used to describe ‘renewable organic resources of biological origin, excluding fossil fuels’, and its share has been increasing in recent years.

Biomass includes woody biomass from forestry and other sources such as corn, but I am particularly interested in livestock manure. Dairy farming and agriculture have developed as key industries in Hokkaido, so there is a considerable amount of related biomass. When livestock manure and waste are fermented by microorganisms, gas is produced. Like natural gas, methane is the main component and is called biogas. It is not a depleting resource like coal or oil, and is advantageous because it is derived from materials that would otherwise be discarded or incinerated, but can instead be used as an energy source.

Each dairy cow produces about 65 kg of manure every day. According to our research results, one tonne of cow manure produces about 30-35 cubic meters of biogas. About 55% of this can be used as methane gas. In Hokkaido, about 800,000 dairy cows are kept, so a simple calculation yields about 1.2 million kWh of electricity per day. This is equivalent to the electricity needed to power 130,000 households (Hokkaido had 2.5 million households in 2020).

A facility that produces biogas from biomass is called a biogas plant. The first biogas plant installed at a testing and research institute in Hokkaido was at my alma mater, Rakuno Gakuen University, followed by Hokkaido University. These plants were designed for cattle manure from ranches only. At present, about 140 biogas plants are installed in various locations in Hokkaido, ranging from small-scale plants for individual farmers to large-scale plants managed by local governments such as Shikaoi Town.

Challenges for biogas generators

The principle of simultaneous demand and supply of electricity states that the amount of electricity produced by a power station must always be equal to the amount of electricity used. If this balance is lost, the frequency of the electricity can change, causing electrical equipment to break down or, in the worst-case scenario, a major blackout. Therefore, when there is a possibility of generating electricity in excess of demand, it is necessary to control the output of thermal power generation, adjust the electricity by pumping hydropower (pumping water from dams), or use the transmission lines connected to the mainland to supply electricity outside the Prefecture.

However, it is very challenging to take advantage of the characteristics of different types of power plants while maintaining a stable supply of electricity, so it is not enough to produce a lot of renewable energy either, but it must be planned in conjunction with other forms of power generation.

Therefore, biogas power generation also requires control technology that generates power all at once when power is needed and curbs output when there is enough. Biogas power generation works by burning biogas containing methane gas and converting it into electrical energy, and takes a relatively long time to reach the rated output. For this reason, our research group has investigated the time it takes to reach the specified value after issuing a command and other power generation characteristics for each generator manufacturer and composition of the biogas used for combustion, and published the results in a paper.

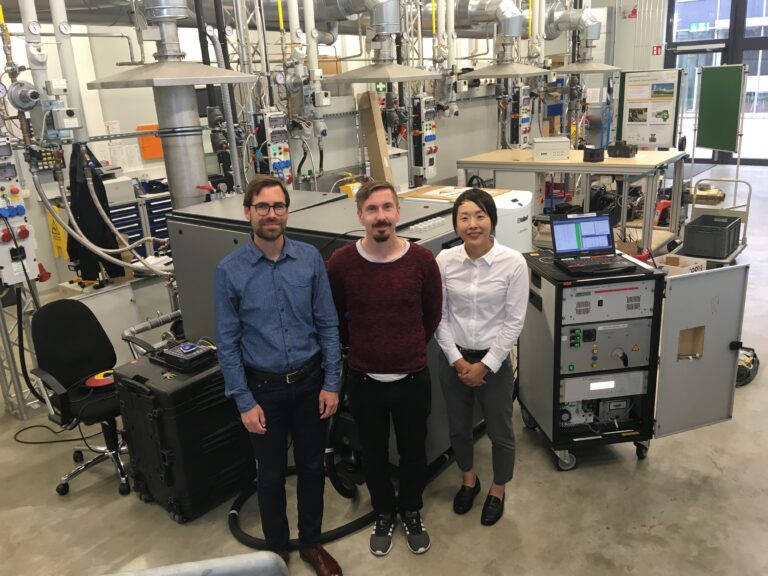

In order to further increase the use of renewable energy, I believe it is also important to expand the options for the use of biogas power generation. I am currently working with researchers in Germany to investigate ways to use biogas more effectively. For example, in addition to power generation and heat use, we are also researching ways to extract hydrogen from biogas to use the energy more efficiently in an environmentally friendly way. Once methane is converted into hydrogen, it can be stored and transported, so I have high hopes for it as a new energy carrier made from biomass.

Measurement of methane in cattle breath

One other major theme that we are working on is the measurement of methane from cattle breath. When cattle break down feed in their stomachs, methane is produced. This is expelled into the atmosphere through the mouth and nose as a result of stomach movement. This phenomenon is known as ‘cow burping.’

The current mainstream method for measuring methane emissions in cattle is the respiration chamber method. This is a very accurate method, but it requires cows to be placed in a private room, which can be stressful for cows and does not reflect the cow’s natural behavioral characteristics, or is difficult to extend the target population.

We therefore use laser methane detectors to make measurements. It is a laser pointer-like device that can be placed on the nose of a cow to measure the concentration of methane emissions. Unlike the chamber method, we cannot measure emission amounts, but we can measure ‘methane concentration’ very simply and with less stress on the cows. We believe that this may reveal some relationship between cattle behavior and high methane emissions.

My research is based on the hypothesis that comfortable conditions for livestock are when there is good husbandry management, both for the environment and for the dairy farmer.

Using IoT to make livestock facilities smarter

Dairy farmers have their living space and the workplace where the barn is located very close to each other. Therefore, rather than spending a lot of money to install a large management system, it is important to have a system that is tailored to the characteristics of the barn and supports a little awareness of the barn’s environment.

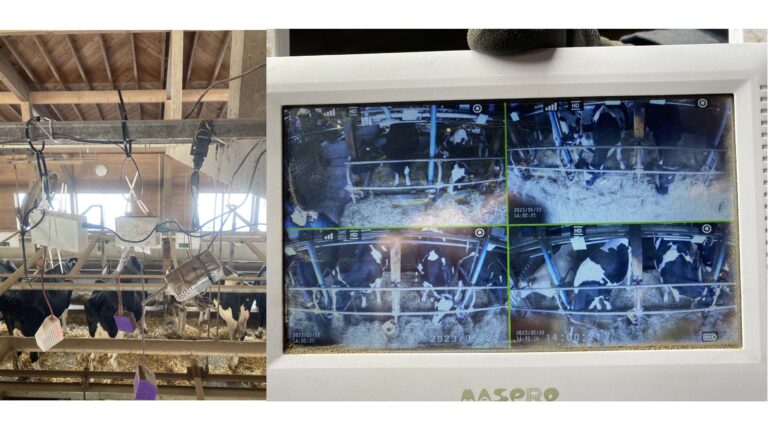

Currently, we are working with professors from the Faculty of Agriculture and the Faculty of Information Science and Technology to develop a smart integrated system for dairy farms that utilizes cloud systems.

This will quantitatively assess factors for a comfortable husbandry or working environment by recording, storing and immediately analyzing real-time video images of cattle and various sensor data in a cross-sectional manner. The system uses general-purpose sensors and home-made devices produced utilizing 3D printers and other equipment, so it is easy to replace them if they break.

For example, cows are sensitive to heat, so the farmers normally run the ventilation fan at high speed in summer, but if the health of the cows can be quantitatively evaluated, it is possible to automatically turn off the fan when it is excessive. This would be comfortable for the cows, convenient for the dairy farmer and environmentally friendly by saving energy.

The research is being conducted across research institutes, where each researcher is challenged to use his or her own specialization to achieve a major goal.

Change from the community, with ‘circulation’ as the keyword

Agricultural issues are not only linked to climate change and energy, but also to food issues. In fact, after the fermentation process in biogas plants, the biomass produces a liquid fertilizer called digestate. This is used as fertilizer to improve food production in various regions.

We believe that the basic principle is a ‘circulation farming’ of creating healthy soil, feeding good food to the cows and returning the waste back to the farmland. If recycling livestock manure can help dairy farmers reduce the labor burden and costs of manure disposal, this should also create a good cycle.

While looking at the global situation, I now feel a sense of fulfillment in carefully resolving local issues in front of me, one at a time.

Make time for nothingness on holidays.

I usually think about research and students, so on my days off I dare to make time to not think about anything. I like exercising in particular, so I regularly go to the gym. When I applied for the gym membership, I was asked, ‘What is your goal?’, so I told them, ‘It’s to become nothing’ (laughs). The gym trainer is very demanding, so I am able to achieve nothingness in a good way.

Once a year for the past three years, I have participated in the Sapporo Dome Relay Marathon with my students, where we compete to see how many laps we can complete around the track in six hours, and last year we came 20th out of 230 teams. This is something to be proud of, as we were all an amateur team. We have graduates from outside the province, so one of the things we look forward to is having a party with everyone afterward.

Written by Space-Time Inc.

Published on December 25, 2024