Spotlight on Research: Safety first in snow clearing works using AI-enabled technology

Research Highlight | February 16, 2023

Snow removal is a winter routine in snow-laden regions, such as Hokkaido, that requires many resources—time, manpower, and machines—but is exposed to many working hazards. For this reason, Associate Professor Takanori Emaru (Laboratory of Precision Metrology and Robotics, Graduate School of Engineering) is developing all sorts of apparatus to enhance its safety.

Associate Professor Takanori Emaru (far left) and the students after demonstration test for the snowplow sensor (Photo by Miho Nagao)

The Laboratory of Precision Metrology and Robotics bases their projects on robot technology, information technology, and AI (Artificial Intelligence) to solve issues in human’s daily life, such as the issue of safety of snow clearing jobs. Generally, snow removal work using snowplows are carried out during nighttime where lighting is minimal. At least one person carries out the role as a guide and walks in front of the moving snowplow operated by the driver.

“In Sapporo, the snow clearance from the public roads take place from around 10 PM to 4 or 5 AM. One guideperson for one snowplow can walk up to 10 km a day. During extreme weather—a whiteout, for instance—the driver’s vision becomes very limited. In short, we are concerned with this dangerous working environment. So, our project’s target is to improve the work’s safety.”

One of Emaru’s many projects concerning this subject is the development of a robust, AI-enabled human-detection sensor for snowplows in joint research with NICHIJO Corporation. The sensor’s robustness lies in its accuracy regardless of the weather conditions. A demonstration test took place inside Hokkaido University’s campus area in the beginning of February 2023 to check the sensor’s performance in real time in the field.

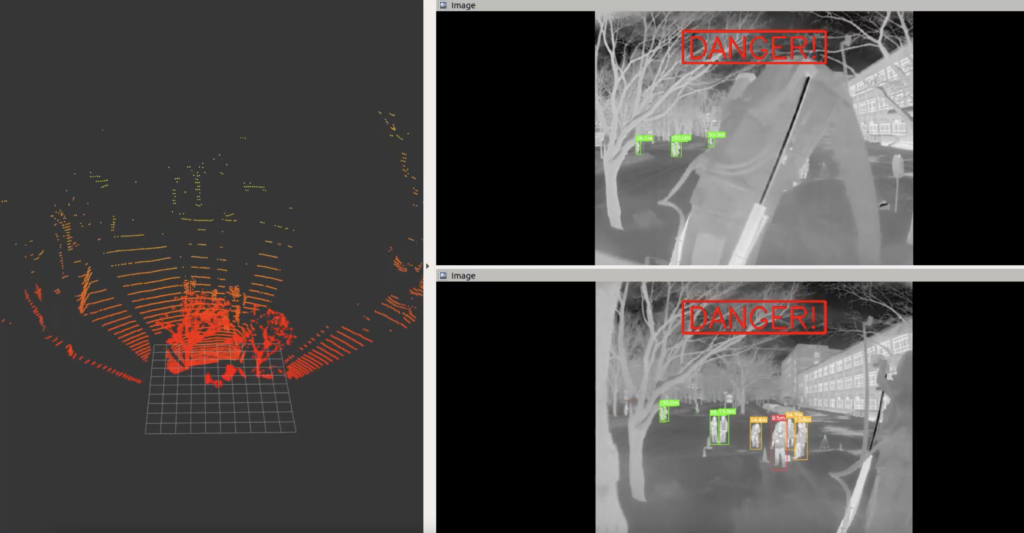

Real-time LiDAR-thermocamera projection as shown on the screen of a laptop connected to the sensor. LiDAR’s 3D map of the snowplow’s surroundings (left) and the sensor’s human-detection screen (right). The top screen is captured by the LiDAR-thermocamera installed on the right-hand side of the snowplow and the bottom screen is captured by the LiDAR-thermocamera on the opposite side. (Image by Takanori Emaru)

Mounted on top of the snowplow, the combination of the sensor’s main components—two sets of LiDARs, RGB camera, and thermocamera—are connected to an alert system that does more than human detections but also calculates the distance in respect to the snowplow. This alert sends a notification to the snowplow operator when a person approaches within 20 meters from the vehicle. If a human is within 10 meters or less from the vehicle, a “DANGER” alert shows up.

“The sensor must also track its own whereabouts. For that, we also installed a GPS antenna on top of the snowplow. However, the standard GPS, like what we have on our smartphones, is accurate only to meter-level. For the snowplow, the GPS is complemented by RTK (Real Time Kinematic positioning), improving the sensor’s self-tracking ability to centimeter-level,” said Emaru.

A video of the sensor’s demonstration test inside the Sapporo Campus area on February 4, 2023. Turn on CC for English captions.

On the other hand, there is also an ongoing issue of labor shortage in Japan. Aiming high, Emaru and his team hope that their projects will eventually lead to the running of a self-driving snowplow. In another related project, supported by the Ministry of Economy, Trade and Industry of Japan, Emaru is developing such a self-driving vehicle. But to hone the snowplow’s versatility, Emaru admitted that it will have to take a longer road into the practical applications. Developing this robust sensor is one way to improve the versatility.

“The hurdle towards the practical application of the self-driving snowplow is still very high. However, this sensor is expected to enter practical applications in three years. Not only by snowplows we also expect it to be used by other heavy machines and vehicles with an affordable cost.”

Written by Aprilia Agatha Gunawan

Researcher’s contact details:

Takanori Emaru

Associate Professor

Laboratory of Precision Metrology and Robotics

Graduate School of Engineering

emaru[at]eng.hokudai.ac.jp